Welcome to karoon khozestan co

- Group:

- Type:

- Brand:

Quality covers

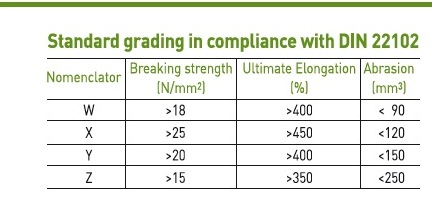

Standard grading in compliance with DIN 22102

Special Grading

“AA" - Extra Abrasion-proof

For belts which have to operate with highly abrasive materials, there is a special grade of material (corresponding to an improved version of grade W in the above table) with a breaking strain higher than 20/N mm2 and abrasion lower than 80 mm3.

“AC” – Tear resistant

For uses where the characteristics of the transported materials cause frequent rips and tears in the belt surface coating there is a special tear resistant grade of coating (similar to the material used on the wheels of large four-wheel drive vehicles which operate under extreme conditions).

“S” – Flame-proof underground use

For uses in underground mines in compliance with current laws and regulations, we supply a series of “S” grade fire-proof, anti-static belts, which conform to the DIN and ISO standards. Said belts avoid the propagation of fire, the generation of electrical charges, or the generation of heat as a result of friction, which could cause inflammable gases to ignite.

“K” – Flame-proof for above ground

For uses in outdoor installations (such as mines, coal yards, or power stations, etc.) we recommend, due to the constant risk of fire, the use of “K” grade fire-proof, anti-static covers (DIN standard) which avoid the propagation of fire.

“KG” – Flame-proof and oil resistant, for above ground

For the transportation of carboniferous materials or similar, with a high content of oil-based substances, and in order to prevent chemical agents in said materials from attacking the rubber cover of the fire-proof, anti-static conveyor belt, we recommend the application of special compounds which make the coating more resistant to degradation. For such cases we recommend the use of “KG” belts.

“SG” - Flame-proof and oil resistant, for underground use

Used in installations where oil-bearing materials are transported and protection is required to prevent possible fires and their propagation. These belts are frequently used for bucket elevators employed with all kinds of cereals and in maritime terminals for the unloading of grain.

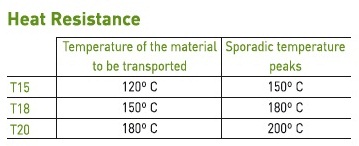

Heat Resistance

The T15 conveyor belt, with SBR rubber covers, is suitable for the transportation of solid materials of a high or medium grading, with maximum temperatures of 120'C and sporadic peaks of 150'C.

The T18 conveyor belt, with EPDM rubber covers, is suitable for the transportation of solid materials of a high or medium grading, with maximum temperatures of 150'C and sporadic peaks of 180'C.

The T20 conveyor belt, with EPDM rubber covers, is suitable for the transportation of solid materials of a medium grading, with maximum temperatures of 180'C and sporadic peaks of 200'C.

For these types of uses and in both cases (a. and b.) we recommend that the textile core, the diameters of the drums and the thickness of the covers all be oversized, in order to compensate for wear due to the ageing of the materials. We recommend minimum thicknesses for the covers of around 5+2 mm.

In the special case of transporting fine and extremely fine graded materials we recommend that the upper covers be increased in thickness by at least 2mm (and should never be less than 6 mm).

“C” – Resistant to Chemical Products

Any type of transportation operation which involves contact with products which could affect the characteristics of general use rubber may be resolved by employing a more suitable grade of rubber. In each particular case our Laboratory will recommend the best possible solution.

“NITER” – Moderate Heat Resistance and Resistance to Animal and Vegetable Oils

(MOR)

In order to address ever more complex transportation requirements Kauman has developed a rubber compound which in addition to possessing excellent physical-mechanical characteristics, also demonstrates correct behaviour when exposed to the following elements (due to the materials transported or due to environmental conditions): the presence of moderate oils; and medium-high temperatures up to a maximum of 130????C.

Neoprene

For use in working conditions where moderate resistance to oils, temperature, acids and marine atmospheric conditions is required.

Resistance to Oil and Grease

When the belt comes into contact with lubricants, grease, waste, etc. the rubber used must demonstrate appropriate resistance to contact with these materials.

Kauman offers two types of oil resistant belts: “type “G” and type “GG”.

“G” – MOR

Specifically for use in the continuous transportation of solid materials which contain or may contain oils, or their derivatives of an animal or vegetable origin.

“GG” – SOR

Specifically for use in the continuous transportation of solid materials which contain or may contain oil derivates or mineral greases: diesel, kerosene, demoulding agents, etc.

“GPVC”

Specifically for use in the continuous transportation of solid materials containing oil or grease derivatives, manufactured in black, blue or white. Other colours are available on request from the customer.

Both belts are manufactured with acrylonitriles of different content, in accordance with the different kinds of operations to be performed.

Depending on the work conditions and the type of material, our Laboratory will recommend the most suitable grade of material for each specific use.

WHITE RUBBER

In addition to the above, and for diverse transportation motives, white or coloured, non-toxic belts are also manufactured, in order to address a multiplicity of potential uses and requirements.

Taking all of this into account, we have classified the belts as follows:

“BL” - WHITE

To avoid possible staining of the transported materials (as in the case of the manufacture of detergents). These belts are generally manufactured in light colours or in blue, grey or cream.

“BLF” – SANITARY WHITE

For this type of transportation, we use grades of rubber which cannot transmit flavours to the transported materials, and which involve no risk of intoxication, as per the international regulations governing these types of products. These belts are normally manufactured in light colours, though they may also be manufactured in black.

“BLW” – White Extra Abrasion-proof

Belt recommended for the transportation of oil-bearing materials and/or where high temperatures are present.

“BLS” – White Flame-proof and Anti-static

Recommended for use in installations where there is a risk of explosion or combustion, to prevent the belt from catching fire.

“BLGP” – White PVC Oil

Type of belt which is a mixture between nitrile PVC and rubber, allowing it to be used for the transportation of materials with a moderate presence of oils, such as animal fats, cereals, etc. This type of belt is manufactured at very low thicknesses and is suitable for small diameter drums.

The belt may be manufactured in light colours or even black, whilst still retaining all of its original properties.

In addition to the described characteristics, and in keeping with all of the belts which are manufactured by Kauman, our conveyor belts are: rotproof, highly resistant to temperatures, resistant to cold, stable and long-lasting, abrasion-proof, and have a controllable amount of elongation, etc.

For more information and buy equipments , kindly contact sales department.